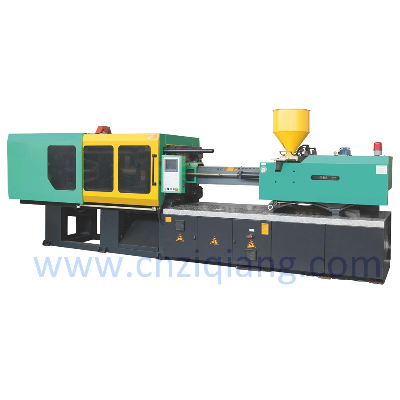

20 Liter Plastic Preform Injection Moulding MachineModel: ZQ88-M6,

ZQ128-M6, ZQ168-M6, ZQ218-M6, ZQ268-M6, ZQ320-M6, ZQ400-M6,

ZQ500-M6, ZQ680-M6 Clamping Force: 880KN---6800KN Shot Weight:

1---4Kg Shot Volume: 129cm3---3808cm3 The technical advantages of

injection machine. Water Saving: No overflowing heating, low oil

temperature saves cooling water, And increases life of sealing

elements. Power Saving: Save Power30%-60%. High Speed: Increase 20%

performance capacity by using variable displacement pump. Oil

Saving: Using high performance filter device to increase life

hydraulic oil. Features. (A) Injection Unit: Double cylinder

cylinder balanced plastic injection Multi-level pressure and speed

for injection High torsion and five-star motor preplasticizing

driven (B) Hydraulic Unit: Differential mould clamping control

Doubleration of pressure and flow Optimize combination Of world

famous branded hydraulic parts (C) Clamping Unit: Clamping quickly

and stoping slowly Automatic gear adjusting Storage type automatic

lubricating & oiling system (D) Electric Control: Controlled by

specialied computer for injection machinery Large LCD screen

display---clear Dynamic display of machine movements---visual (E)

Oil-supplying unit: The international advanced technology The

automatic oil-supplying device adopted Standard Equipments: (1)

Double-Cylinder Balance injection System (2) Multi-stage

Pressure&Speed injection Adjustment (3) Back-pressure

Adjustment & Control (4) Decompression (5) High Speed

mould-Clamping Device (6) Low Pressure mould Protection (7)

Multiple Ejector Style (8) Mechanical, Electrical&Hydraulic

Safety Device (9) Centralized Lubrication (10) Proportional

Pressure&Flow Control (11) All Computer Control System (12)

Data Locking Function/Mould Memory System (13) Large Screen of LCD

(14) Linear Displacement Transducer Controlling injection,

Clamping&Ejection (15) Electronic&Hydraulic Control

Component&Elements of The World Famous Brands 20 Liter Plastic

Preform Injection Moulding Machine,equipment information. INJECTION

MOLDING MACHINEZQ400-M6ZQ500-M6ZQ680-M6International size

rating2856/4002856/5004598/680INJECTIONABCABCABCShot

volume cm3138518092289159020422550249631173808Shot

weight

g130017002150149419192397227128733465(PS)

oz45.659.575.352.367.283.979.599.3121Screw

diameter mm7080907585958595105Injection pressure

Mpa206158125180140112191153125Screw L: Dratio

-----24:121:119:123.2:121:118.7:123.5:121:119.5:1Screw

stroke mm360360440Screw speed

(stepless) r/min0-1350-1320-160CLAMPING

SYSTEMZQ400-M6ZQ500-M6ZQ680-M6Clamping

force KN400050006800Opening

stroke mm660780920Platen size

mm×mm1050×10501155×11551395×1395Space between tie bars

mm×mm730×710830×830930×930Max.daylight

mm139016001830Mold thickness (Min-Max)

mm250-730300-820350-910Hydraulic ejection

stroke mm185210265Hydraulic ejection

force KN111111182POWER

UNITZQ400-M6ZQ500-M6ZQ680-M6Hydraulic system

pressure Mpa17.517.517.5Pump

motor KW374555Heating capticy

KW23.22735.4Number of temp control

zones5+(nozzle)5+(nozzle)6+(nozzle)GENERALZQ400-M6ZQ500-M6ZQ680-M6Dry-cycle

time Sec5.15.26Oil tank capacity L95011501500Machine

dimensions(LxWxH) M x M x

M8.50x1.88x2.458.97x1.98x2.459.76x2.37x3.29Machine

weight Kg170002200036000Note: The specifications are

subject to change without notice for the further improvement.

/* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about 20 Liter Plastic Preform Injection Moulding Machine (ZQ680-M6)

-

Automatic Plastic Pet Bottle Blowing Machine with CE

Automatic Plastic Pet Bottle Blowing Machine with CE

-

Automatic Plastic Pet Bottle Blowing Machine with CE

Automatic Plastic Pet Bottle Blowing Machine with CE

-

Plastic Pet Preform Injection Mold Hot Runner (Shut-Off Nozzle) (48 Cavities)

Plastic Pet Preform Injection Mold Hot Runner (Shut-Off Nozzle) (48 Cavities)

-

PET Preform Mould with Hot Runner System (72 Cavities)

PET Preform Mould with Hot Runner System (72 Cavities)

-

Plastic Pet Preform Injection Mold Hot Runner (Shut-Off Nozzle) (48 Cavities)

Plastic Pet Preform Injection Mold Hot Runner (Shut-Off Nozzle) (48 Cavities)

-

Plastic Pet Preform Injection Molding Machine Price (ZQ500-M6)

Plastic Pet Preform Injection Molding Machine Price (ZQ500-M6)

-

Plastic Pet Preform Injection Molding Machine Price (ZQ500-M6)

Plastic Pet Preform Injection Molding Machine Price (ZQ500-M6)

-

High Speed 5 Liter Plastic Pet Bottle Making Machine Price by CE

High Speed 5 Liter Plastic Pet Bottle Making Machine Price by CE