Product DescriptionIndustry Paper Mill Use Paper Making Machine

Polyester Forming WirePolyester Forming Wire is used

paper-making on a paper machine so it is also called paper

machine clothing or paper making fabric. Polyester forming

fabric can be divided into 4-shed, 5-shed, 8-shed,

16-shed, 20-shed and 24-shed according to the

weaving type, etc. It can also be divided into

single layer fabric, double layer fabric, two-and-a half layer

fabric and three-layer fabric according to the

category.SeriesApplicantMachine Speed4-shed , 5-shed series single

layer polyester forming fabricsproducing cultural paper (single

glue, double glue and color glue), printing paper, glazed paper,

packing paper, common newsprintcommon fourdrinier paper

machine8-shed single layer polyester forming fabrickraft paper,

cardboard , corrugated paper making, common printing papercommon

fourdrinier paper machine8-shed double layer fabricquality printing

paper. For example ,dictionary paper, offset printing paper,

newsprint and wrap paper, tissue paper making and the surface

pulp, lining pulp, core pulp and bottom pulp of the board paper

etcmedium and high speed paper making machine16-shed double and a

half layer polyester forming fabricquality printing paper, such as

offset printing paper, copper plate paper, newsprint and cigarette

paper series (wrap paper and filter tips paper), toilet paper,

tissue paper and surface pulp, lining pulp, core pulp and bottom

pulp of the board paper etc.medium and high speed paper making

machineMulti-shed three-layer fabricquality printing paper, tissue

paper and cigarette paper etchigh speed paper making

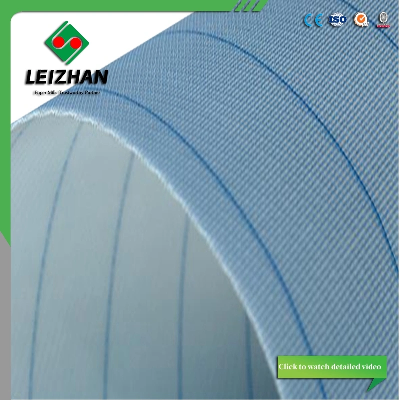

machineDetailed PhotosSingle & 1.5 LayerSingle & 1.5 layer paper

making forming wireWeaving series & typeFabric ModelWire Diameter

mmDensity(root/cm)Tensile strengthTicknessmmAir

PermeabilityM3/m2hForce elongation(in 50N/cm Tension,Tension rate

not more than)WarpWeftWarpWeftSurfaceJoint4-shed single layer

forming

fabricSFW272540.200.252922≥600≥4000.497500±5000.60%SFW272740.200.273022.5≥600≥4000.517600±5000.60%SFW312540.200.223528≥600≥3800.436500±5000.68%5-shed

single layer forming

fabricSFW272150.200.253023≥600≥3500.57600±5000.60%SFW272850.220.283023≥600≥5000.487800±5000.60%SFW312050.200.213532≥600≥4000.486700±5000.60%8-shed

1.5 layer forming

fabricSFW253580.220.352819.5≥700≥5000.869000±5000.65%SFW254580.220.3829.519≥700≥5000.888500±5000.65%SFW273580.220.352920≥700≥5000.868500±5000.65%SFW274080.220.4031.519≥700≥5000.888000±5000.65%Double

& 2.5 Layer2 & 2.5 layer paper making forming wireFabric ModelWire

Diameter mmDensity(root/cm)Tensile strengthAir

PermeabilityFSIDIWarpWeftWarpWeftSurfaceJointM3/m2hCFM2H56080.170.18

0.13/0.25

0.2562.5-63.551.0-52.0≥850≥650600038012126.92H56160.170.20

0.13/0.30 0.3062.5-63.560.5-61.5≥1500≥1300450028513923.90.20

0.13/0.30 0.3053.5-54.5≥1500≥1300550035012626.00.20 0.13/0.35

0.3559.5-60.5≥1500≥1300395025013720.60.20 0.13/0.35

0.3556.6-57.5≥1500≥1300450028513122.30.20 0.13/0.35

0.3553.5-54.5≥1500≥1300505032012623.70.20 0.13/0.35

0.3550.5-51.5≥1500≥1300550035012024.60.20 0.13/0.35

0.3547.5-48.5≥1200≥1000600038011525.10.20 0.13/0.40

0.4048.5-49.5≥1250≥1050505032011721.52H32160.220.22 0.13/0.35

0.3547.0-48.047.0-48.0≥1500≥1300600038010724.80.25 0.17/0.40

0.4046.0-47.0≥1500≥1300550035010522.40.25 0.17/0.40

0.4040.0-41.0≥1500≥130070004459424.82H36160.260.30 0.20/0.50

0.5040.5-41.538.5-39.5≥1500≥130055003508918.836.5-37.5≥1500≥130063504008520.434.5-35.5≥1500≥130070004758221.4Triple

(3) LayerSSB 3 layer paper making forming wireFabric ModelWire

Diameter mmDensity(root/cm)Tensile strengthAir

PermeabilityFSIDIWarpWeftWarpWeftSurfaceJointM3/m2hCFM3LSSB42240.22/0.300.22

0.22/0.45

0.4541.5-42.543.5-44.5≥1600≥1400550035011019.641.5-42.5≥1600≥1400635040010721.339.5-40.5≥1600≥1400700044510322.637.5-38.5≥1600≥1400800050510024.43LSSB42200.22/0.30

0.22 0.22/0.45

0.4541.5-42.549.5-50.5≥1600≥1400550035011922.247.5-48.5≥1600≥1400700044511527.10.22/0.280.22

0.22/0.50

0.5045.5-46.5≥1600≥1400635040011323.442.5-43.5≥1600≥1400700044510824.339.5-40.5≥1600≥1400800050510325.7Packaging

& ShippingCompany ProfileWe are a China industrial felt and fabric

manufacturer located at Jiangsu province,Xuzhou city. With

advantage technology and excellent produce equipment,we provide

one-stop service from consultation,process design and optimization

, manufacture ,installation , commissioning and

personnel training and so on.At the meantime,we can custom design

according to customers' requirements. Now, in addition to providing

high-quality products and basic services, we pay more attention to

providing customers with technical support and a complete set of

solutions. Through our professional analysis, we can reduce

customers' costs, enhance their competitiveness, and provide

customers with one-stop industrial fabric solutions.Leizhan

corporate spirit : "Unity, innovation, pragmatism, and

truth-seeking".Since the establishment of Leizhan, we have insisted

on taking customer needs as our core, thinking about what

Related products about Synthetic Forming Wire Mesh Fabric for Paper Machine Mills

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup