Product

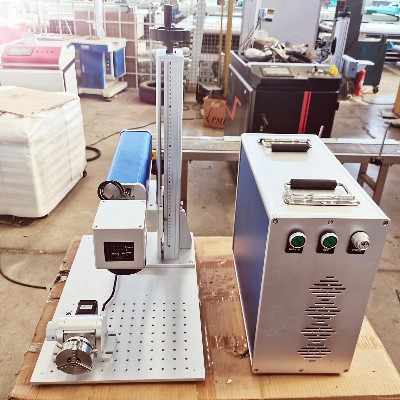

DescriptionModelST-F20ST-F30ST-F50ST-F60ST-F70ST-F80ST-F100Average

Output Power20W30W50W60W70W80W100WApplicationFiber Laser

MarkingLaser Source BrandRAYCUS, MAX, JPT, IPGSoftwareBJJCZ

EZCADLaser Life100000+ hoursWorking

Format50*50/110*110/150*150/200*200/260*260/300*300mm, etc.Working

Accuracy±0.001mmLaser Wavelength1064nmWorking Power Supply220V/50HZ

or 110V/60HZWorking Temperate-10ºC~40ºC / 14ºF~104ºFCooling

methodAir cooledMachine Size210*450*440mmMass Weight60KGAppication

MaterialMetal: Gold, Silver, Brass, Copper, Carbon Steel, Stainless

Steel, Aluminum, Anodized Aluminum, Titanium, ChromeHard Plastic:

PF, PU, EP, UPR, FF, SI, ANOptionalRotary Axis / Lifting Table /

Auto Lifting Table / AutofocusDetailed PhotosWhat Is Fiber Laser

Marking Machine?Fiber laser making machine is a new type of CNC

laser engraving system that uses fiber laser generator to etch a

permanent mark on 2D & 3D surfaces of metals, nonmetals, and

metalloids, which is used in hobbyist, small business, small shop,

home use, home business, school education, commercial use, and

industrial manufacturing.It uses a high-energy 1064nm laser beam to

remove excess parts on the surface of the substrate and engrave

permanent photos, patterns, or text. Its professional for fine

metal engraving with high precision, high quality, and high

speed.With a rotary attachment, it can etch on cylinders such as

pens, rings, tools, cups, mugs, and tumblers. With the MOPA laser

source, color engraving can be performed on stainless steel and

titanium. The higher laser power allows deep engraving of metals

and even cutting of thin metals.In some technological occasions,

such as molds, guns, jewellery, auto parts and conventional

materials such as steel, ceramics, gold, silver, copper and

aluminum in the aerospace industry, as well as new materials such

as silicon carbide, nickel-chromium alloys, and thermal barrier

coatings.It is necessary to The outer layer is stripped deeply to

achieve a clearer visual result (such as dots, lines, notches,

etc.) and to facilitate subsequent processes (such as plate making,

painting, welding). In addition, because the marking object must be

placed in a harsh environment, the adhesion of the marking result

is very high, and the marking needs to be deeply attached to the

base material without peeling off due to weather, humidity,

external force, etc. Fiber Laser Deep Engraving Machine

for Metal Projects:Fiber laser marking machines are widely used in

all walks of life, as long as they need to be marked. From an

industry perspective, these types of engravers are widely used in

computer accessories, integrated circuit chips, clocks and watches,

industrial bearings, electronic components, auto parts, aerospace

devices, home appliances, molds, wires and cables, hardware tools,

food graphic and text markings in jewelry, packaging, credit card,

tobacco, and more fields, as well as industrial mass production,

assembly line production, and high-end ultra-fine printing.

Sample DisplayPackaging & ShippingLaser equipment is a relatively

precise machine, beware of bump and friction in the process of

transportation, which requires us to do a good job of packaging

before transportation. Morita, as a professional manufacturer of

laser equipment in China, has a lot of experience in packaging all

kinds of laser equipment.1. Wipe the machine, the machine is wiped

clean, not only for beautiful, more important is to prevent the

machine attached to the machine is in the process of transport of

particles cut surface, damage the paint. 2. We will use

stretch film to winding machine,let the machine with a layer of

protective film, this is to let the machine during transport to

prevent damage in the process offriction. 3. We'll let the

machine then wrapped with thick foam board, this can prevent

machine in the process of transportation by knock against,

impact. 4. Installation of wooden boxes, thick wooden cases

like a layer of armor, can protect the machine to agreat

extent. 5. In front of the cover in the middle of the machine

and the cases filled with rubber cushion, this will prevent

collision between machines and wooden case, can also further to

package the machine. From CustomersCompany Profile· With 15

years experience, MORITA LASER has established a complete system

for the development and manufacture of laser marking, cutting,

engraving and welding technologies.· Main products: fiber laser

cutting machine, fiber laser marking machine, crystal engraving

machine, CO2 laser marking machine, UV laser marking machine, laser

engraving machine, laser cutting machine, CNC engraving machine,

CNC processing center, stone engraving machine and other products.

As a responsible company, we are dedicated to develop new

techniques out of concern of environmental protection. Disposable

products are the first priority. In the near future, we will launch

more and more environmental friendly products.FAQQ1: Is your

company a manufacturer or a trading

Related products about Fiber Laser Marking Engraving Cutting Machine with Jpt Sinogalvo Bjjcz for Metal Mould/Relief/Curved Surface/Jewelry

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup